Principles of UV LED technology

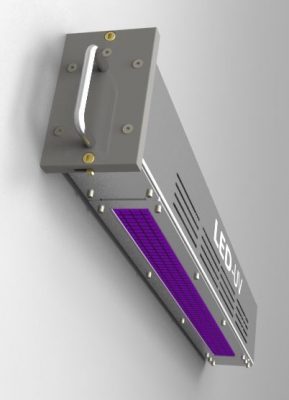

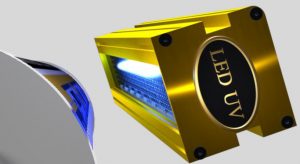

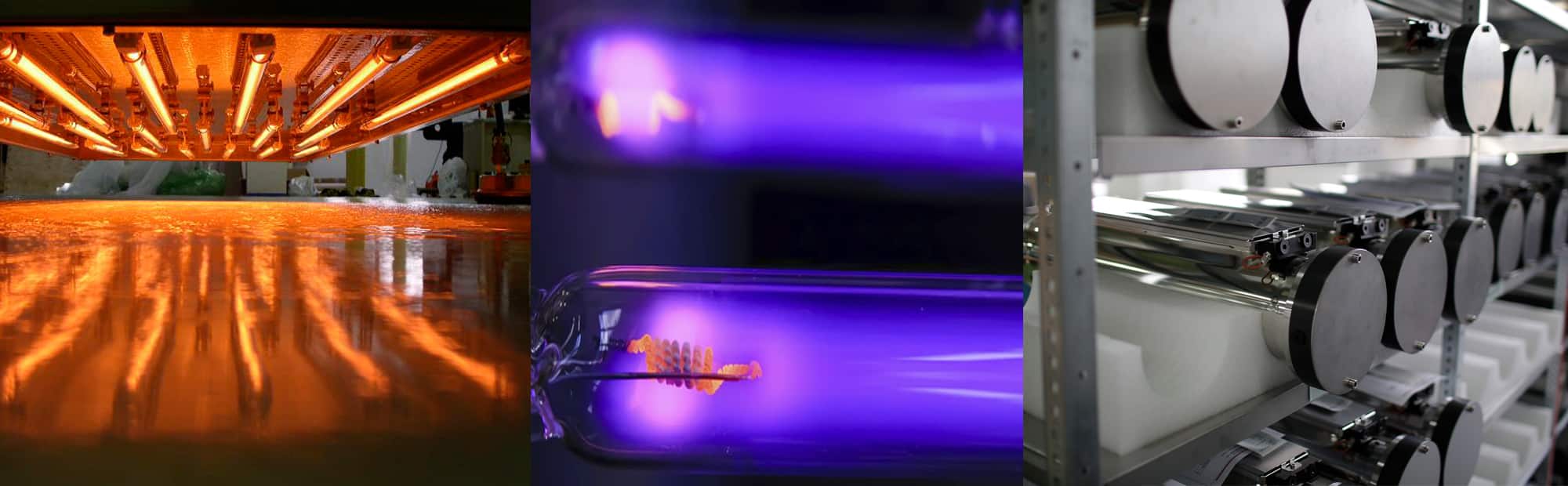

Besides UV arc lamps, LED systems have seen increasing use in industrial curing since beginning of 2000. When LEDs (LED is an abbreviation of the English “light-emitting diode”) are used in industrial applications, they are combined in small construction units to suit the output required.

UV LEDs are arranged in several smaller units, depending on the required output. The resulting modules can contain 100 or more LEDs. These LEDs are controlled via intelligent circuit and be controlled in zones. It is then possible to adapt the LEDs to the working width.

The challenge is to ensure that the LED light emitted reaches the substrate with as little loss as possible. When doing so, optical decoupling is of critical importance.

BENEFITS OF LED CURING TECHNOLOGY.

- Instant readiness for use

- Clocking

- No ozone

- No mercury

- Low penetration of heat into the substrate

- High-frequency cycle operation

- Low heat input

- High efficiency

- Ready to use as soon as switched on

- Either water cooling OR air cooling

- Energy-saving potential

- Long service life

- Compact size

MEASURING TECHNOLOGY FOR LED SYSTEMS

W/cm² has become the established unit of measurement in LED systems. This value indicates the maximum intensity per unit of area. However, since the intensity decreases with increasing distance, the value directly below the exit window is often cited. For comparable measurements, the location at which the power was measured is decisive. Values can vary depending on whether measurements are taken at the chip surface, at the exit window of the emission or at the substrate level. The spatial and temporal distribution in the measuring field must also be taken into account.

LED UV IS ALREADY USED IN MANY INDUSTRIES.

LED UV systems are used both in the printing industry and in numerous other industries on various substrates where coatings and adhesives play a role, such as decoration, marking, joints, fixings, mechanical protection, and chemical protection.

In principle, there is a variety of potential applications for LED curing technology in the industrial drying of inks, varnishes, silicones, seals or adhesives on different substrates. Retrofitting is also a possibility.

If you are investigating newprojects, contact us! We will be pleased to help.